Rotatable Thermal Evaporating Coater MNT-TEC-1800

This price is only available upon request. Contact us for a quote or fill the request form at the bottom of this page.

General Introduction

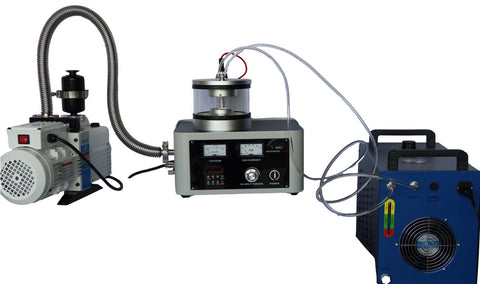

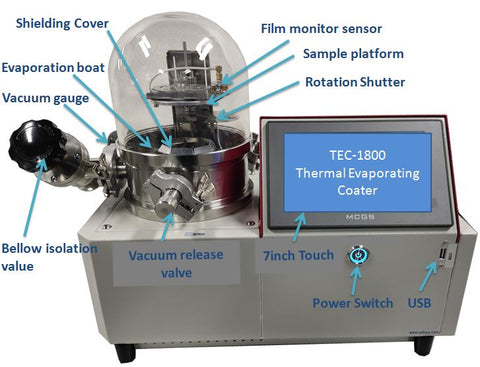

The MNT-TEC-1800 is a compact, bench-top thermal evaporating coater designed with precision temperature control up to 1800 °C (3272 °F). Despite its small footprint, it offers full functionality and advanced features, including voltage and current feedback, a rotating sample stage for uniform substrate deposition, and adjustable sample height to minimize the use of costly materials.

A motorized shutter enhances coating uniformity and purity by enabling controlled evaporation and deposition of most metals. Combined with programmable preheating and evaporation power settings, it provides precise process control.

The transparent quartz glass vacuum chamber helps reduce sample contamination and allows easy observation during operation. The rotating sample stage ensures consistent, even film deposition, making the system ideal for preparing a wide range of metal and organic thin films.

Features

- Automatic process control on touch screen enabling repeatable coating quality

- Quartz surrounding chamber minimizing the contamination

- Precise temperature control with accuracy of ± 1Cº

- Sample stageφ62, compatible withφ50 substrate

- Working with both included mechanical pump (1Pa) or optional turbopump

- Electric controlled shutter ensures high purity of coating layer

- Rotatable sample stage guarantees uniform deposition thickness

Specifications

|

Rotary Thermal Evaporator Thermal Vapor Deposition Coater MNT-RTE-1600S |

|

|

Control |

7 inch touch screen, manual mode and automatic mode |

|

Input power |

110V, 60 HZ or 208-240V, 50HZ |

|

Coating program |

0-999S, 5 stage process programming; adjustable current and power; shutter control and rotation speed. |

|

Sputtering Power |

DC Thermal Evaporation |

|

Max power |

≤2000W |

|

Output voltage and current |

V≤12V; I≤100A |

|

Sputtering Vacuum |

≤30Pa |

|

Shutter control |

Electric |

|

Vacuum chamber |

Quartz and Stainless steel, φ160xH160mm |

|

Sample stage |

φ62, compatible withφ50 substrate |

|

Sample Stage Rotation speed |

0-8 RPM |

|

Evaporation crucible volume |

70-135mm |

|

Evaporation temperature |

≤1800℃ |

|

Reserved vacuum ports |

KF25 Exhaust Port, KF16 Release Port, 6mm Compression Fitting Inlet Port |

|

Vacuum gauge |

Pirani vacuum gauge (Measuring range: 10E5Pa to 1E-1Pa) |

|

Touch screen |

7 inch |

|

Shutter control |

Electric |

|

Vacuum reachable |

Rotary pump≤ 1 Pa; molecular pump ≤ 0.005 Pa |

|

Overall dimension |

270×440×400mm |

|

Vacuum port, Release valve, and air inlet |

KF25 vacuum outlet, KF16 air release, 6mm air inlet |

|

Mechanical Vacuum pump included |

Option for Molecular Pump |

|

Input power |

AC 110V/60HZ 400W or 220/50HZ |

|

Displacement speed |

60HZ: 1.3L/S (4.8M3/h); 50HZ: 1.1L/S (4M3/h) |

|

Max vacuum |

≤ 5X10-2 Pa |

|

Noise |

≤ 52dB |

|

Control |

Integrated with the main unit or stand alone |

|

Flange |

KF25, Adapters available upon request |

Heating mechanism of the MNT-TEC-1800 thermal evaporating coater:

Rotatable platform, shutter, and quartz crystal oscillator sensor

Adjustable height

Copper on Tungsten boat

Accessories

Five Tungsten boats are included in the package. Please contact us for more Tungsten boats, or other heaters, such as crucibles, tungsten bar et al..