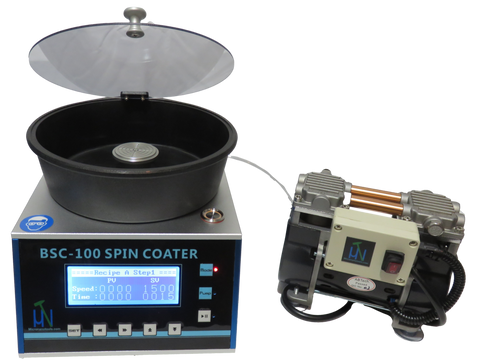

Plasma Sputter Coater MNT-JS1600 with Vacuum Pump, Incl. Gold Target, Free shipping and two years Warranty

General Introduction

MNT-JS1600 is a compact plasma sputtering coater designed for making metallic/conductive oxide coatings, such as gold, platinum, Indium, Palladium, Titanium, Cobalt, and silver et al. The system can be applied on a sample up to 50 mm diameter. Thicker coating can be achieved by repeating the process. It is widely used for coating conductive gold film for SEM sample preparation and for device prototyping in various fields. The plasma sputtering coater is turn-key solution and will be shipped with all necessary accessories for immediate use, including one sputtering head with gold sputtering target installed (gold cathode), a Vacuum pump with a stainless steel bellow hose, KF 25 flanges, and a vapor mist trap.

For coating metals which can be oxidized easily, such as Copper and Aluminum, it is strongly recommended to use a high power magnetron plasma sputter coater MPSC-500RS or at least MNT-JS1600M. Extra challenges are expected when using the MNT-JS1600 for copper and aluminum. Please contact seller for more details.

The plasma sputter coater may be used for some oxides, such as ZnO. The coated ZnO film may not be conductive at lower temperature.

This product is manufactured in Canada according to US and Canada standard (110V/60Hz). Two-year warranty and lifetime support are offered for this product.

MicroNano Tools provides various sputter targets for plasma sputter coater. Please click here for details.

Features

- Compact size and robust design with big sputtering area

- Built in sputtering chamber vacuum gauge and sputtering ampere meter, for monitoring plasma sputtering process conditions

- Adjustable sputtering current, enabling sputtering coating of various metals, such as gold, platinum, Indium and silver etc.

- Hinge clamps are used for all vacuum connections to prevent vacuum leak

- Possible to be used inside a standard glove box

- Possible to be customized to 75 mm sample

Specifications

For details of vacuum pump, please click here.

Warranty

- Two year standard warranty with life-time support; contact for details.

- Damage due to improper storage condition or maintenance is not covered by warranty

- Longer time warranty available upon request

- Client reference available upon request

Partial List of Recent Clients

Magneto Innovations, The Citadel, The Military College of South Carolina, Gannon University, Flux GmbH from Germany, Chroma Color Corporation, Intecs Instrumentación S. A. de C.V. from Mexico, Amastan Technologies, University of Central Florida, Tufts University, Johns Hopkins University, 4C air in California, Impulse Dynamics Inc., IMR From Mexico, University of Western Ontario, Boeing Company, University of Waterloo, Calgary University, IBC Materials & Technologies, Virginia Tech, Idaho National Lab, Virginia Tech, Western Michigan University, OSC Japan, Pacific Northwest National Laboratory, University of Maryland in Baltimore County, University of the District of Columbia, Suncor Energy, Kansas State University, Blue Leaf Development, Alabama University, Meredith College, Suntricity Corporation, Buffalo University, Centre National Des Recherche en Sciences Tunisie, Clemson University, CNRS ARTEMIS in France, Begs Solutions, Systron Donner, Blue Leaf Development, Lehigh University, Zappe Inc., Innovative Ink GmbH in Germany, Techno Lab in Greek. References available upon request.

Additional Notes

- The item is in stock. Lead time of 110/60Hz is 3 business days; the 220V/60Hz sputtering coater may take 5-10 business days;

- Two-year warranty and lifetime support are offered for this product

- Accept custom OEM if there are any special requirements for your application

- All universities and research institutes are entitled to payment term of net 30 days automatically. Before receiving the sputter coater, No Payment, No Worry, No stress, No Risk.

- For European countries, shipping will be handled by DHL Express.

Frequently Asked Questions

1. Working principle of MNT-JS1600 Plasma Sputter Coater

As schematically shown in the following picture, the plasma sputtering process can be summarized as three steps.

2. Does distance between sample and target play any role for coating?

The MNT-JS1600 is a DC two-pole plasma sputtering coating system. The sample under the target receives both the electron bombardment and target deposition as shown in the above picture. With short distance between sample and the target, the coating speed should be increased because less target atoms are scattered to other areas in the vacuum chamber. But the sample may be subject to more electron bombardment, which may result in possible thermal damage to samples to be coated. If samples are rocks, it may not be necessary to worry about temperature increase. For some biological samples and plastic samples or any samples sensitive to temperature, possible thermal damage should be considered and an optimized distance should be practiced.

3. How to estimate coating thickness?

The coating thickness mainly depends on target material, sputtering current, and coating time. Their relation can be described approximately by the following equation:

H=M.I.T,

where H is the coated film thickness; M is material constant, when using Argon gas, approximately 0.17 for Au at a working distance of 50mm (distance between sample and target), 0.09 for Pt, 0.10 for Al (Aluminum); I is the sputtering current, mA; T is the time, second.

When using Argon or Nitrogen, 10mA sputtering current, coating gold for 100S, the film thickness will be about 0.17x10x100=170Å. When using air sputtering, M is about 0.07 for gold. The above equation is for estimation only.

4. Is the sputtering voltage adjustable?

Yes. At certain atmosphere in the sputtering chamber, sputtering voltage can be increased by increasing sputtering current using the adjusting knob. Maximum value of the sputtering voltage is -1600V. However, the sputtering voltage will also change with vacuum atmosphere and target material.

When using gold target and vacuum at about 4Pa and sputtering current at 10mA, the sputtering voltage is about 1300KV; if lower down vacuum to 8Pa and maintain the same sputtering current at 10mA, sputtering voltage is about 550V.